SHARE THIS:

Bringing Butyl Back: The Future is Here with Unirac, Again!

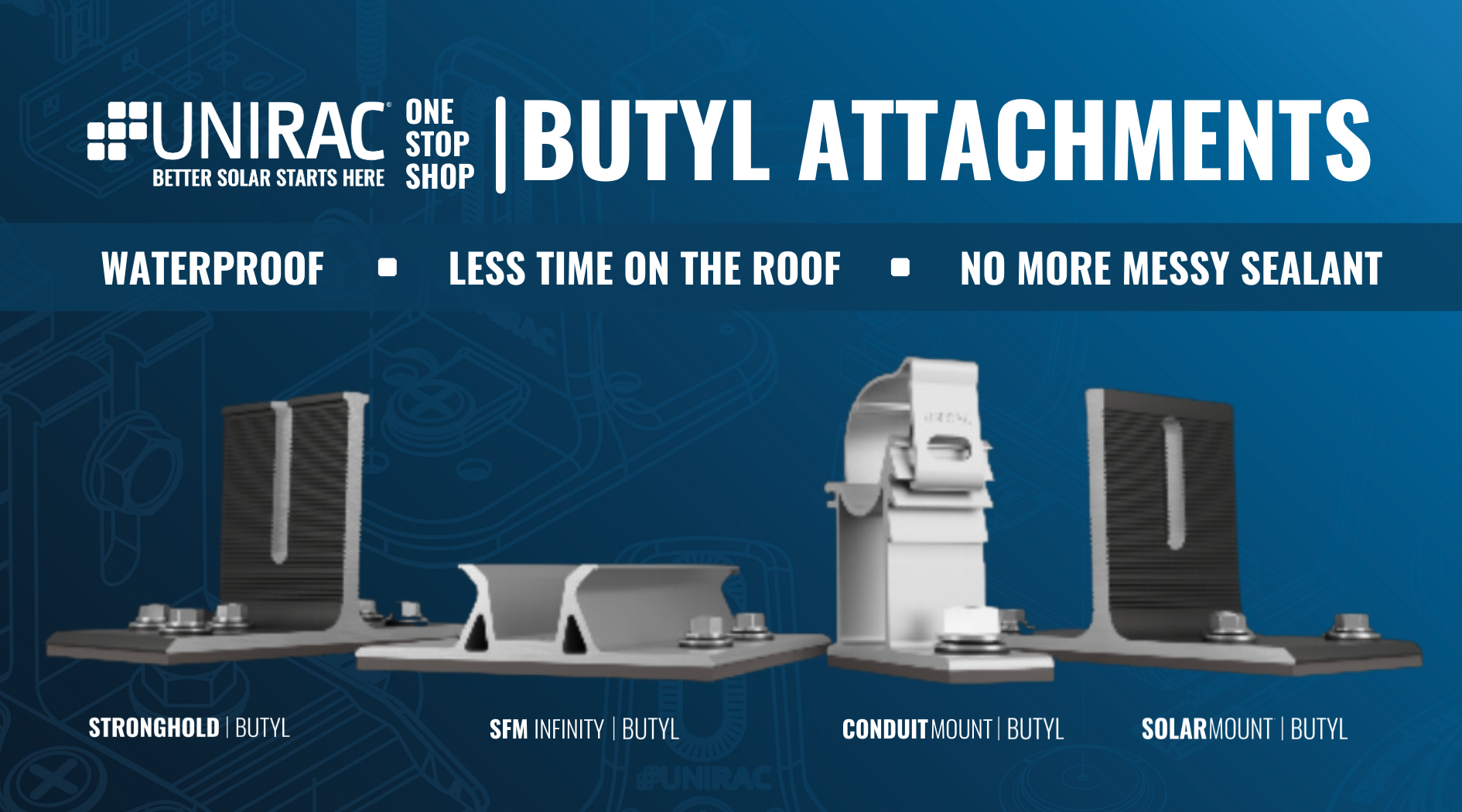

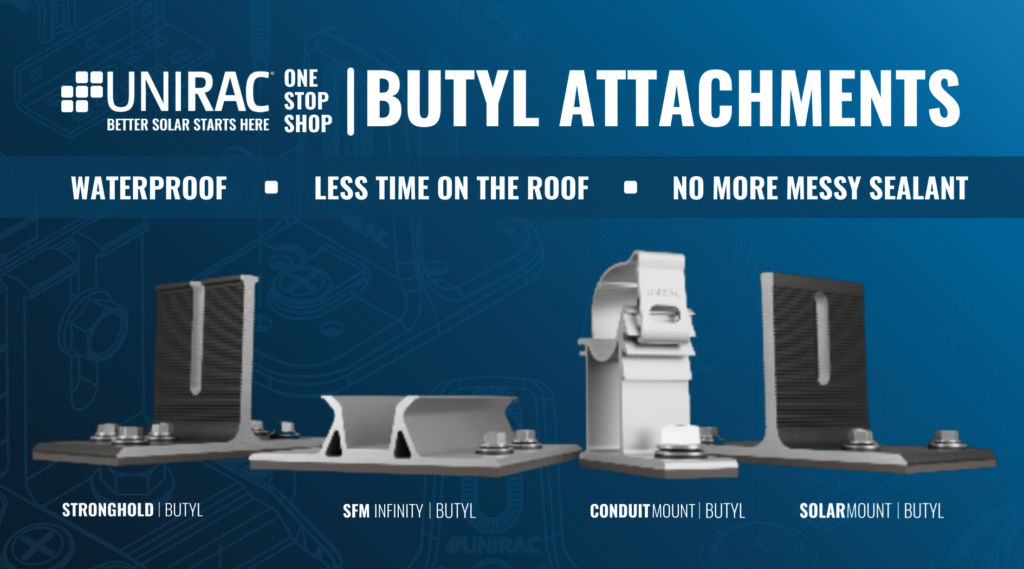

At Unirac, we’ve always prided ourselves on being at the forefront of solar mounting technology. In 2010 we were so far ahead of the innovation curve that we were the first to introduce adhesive flashing that opened the market and enabled a more efficient installation experience. Today, we want to dive deep into that innovation and its significant impact on rooftop solar installations: butyl roof attachments for every pitched roof application. Unirac now offers a butyl solution on a full suite of attachments and conduit mount.

What are Butyl Roof Attachments?

Butyl, a synthetic rubber, has been traditionally used in various industries for its remarkable waterproofing and adhesive properties. When it comes to solar installations, butyl roof attachments refer to mounting systems that use butyl-based sealants or tapes to ensure a watertight seal between the roof and the solar racking system.

Why Butyl is a Game-Changer

Superior Waterproofing: Butyl stands out for its incredible water resistance. By using butyl roof attachments, installers can be confident that the point of attachment is well-sealed against potential leaks.

Extended Lifespan: Butyl maintains its adhesive properties over an extended period, reducing the need for frequent checks and maintenance.

Compatibility: Whether it’s a metal, composite, or asphalt shingle roof, butyl attachments provide a versatile solution suitable for various roofing materials.

Temperature Resistance: Solar installations are exposed to varying temperature ranges. Butyl’s ability to maintain its integrity in both high and low temperatures ensures the longevity of the seal.

Ease of Installation: With the adhesive properties of butyl, there’s no need for additional, complex sealing procedures. This translates to quicker and more efficient installations.

Unirac’s Approach to Butyl Roof Attachments

At Unirac, our approach is to integrate the benefits of butyl into our industry-leading mounting solutions. Here’s how:

Engineered Excellence: We have combined our engineering expertise with the unique properties of butyl to create roof attachments that not only ensure a strong hold but also protect against the elements.

Training and Support: To get the most out of butyl attachments, it’s essential to install them correctly. We offer comprehensive training and support to our partners, ensuring every installation is up to the mark.

Commitment to Innovation: Our R&D team is continually working to push the boundaries of what’s possible with butyl in the solar industry. Expect more cutting-edge solutions as we move forward.

Optimization: We kit all our attachments and that is no different for our butyl products. Each butyl attachment and accessory are kitted with the hardware needed to complete rafter installations. That is one SKU for ease of ordering, stocking, and installation. Direct to deck applications require extra screws and are sold separately as needed.

The Road Ahead

As the solar industry continues to grow and evolve, the demand for reliable, efficient, and innovative mounting solutions will increase. At Unirac, we see butyl roof attachments as a key piece of this future puzzle.

In conclusion, butyl roof attachments represent a merger of traditional material science with modern solar needs. By adopting these solutions, solar installers can ensure that their installations are not only efficient and reliable but also resilient to the elements. With Unirac leading the charge, the future of rooftop solar looks brighter than ever!

Ask your distributor to stock Unirac attachments with butyl today.

Stronghold™ Butyl-

- Dark: SBUTYLD1

- Mill: SBUTYLM1

- Extra deck screws: 003251W

SFM Butyl- SFMBTLM1

Conduit Mount Butyl- EB-CM-01M

SolarMount® Butyl-

- Dark: 004BUTYLD

- Mill: 004BUTYLM

- Extra deck screws: 003251W