HOME » Archives for July 28, 2020

UNIRAC TRAINING GOING STRONG IN FLORIDA AND ACROSS U.S.

SHARE THIS:

Especially in a down economy, every installer is hunting for ways to keep looking ahead and not lose momentum. Unirac’s Installer Sales Specialists have been adjusting to continue bringing our customers as much value as possible in the industry.

One of the services these specialists can offer (thanks to their own backgrounds as installers) is the ability to show products hands-on and answer questions only an installer might have answers to. It’s a role that Unirac takes seriously and encourages specialists in the company to offer its customers regularly.

Take Tom Talmage, Installer Sales Specialist for Florida, for instance. You can learn more about his background in the profile we did of him last month. He recently visited Optimus Solar, a Central Florida company based in Mount Dora, to meet with owner Ben Pauluhn and three of his lead installers.

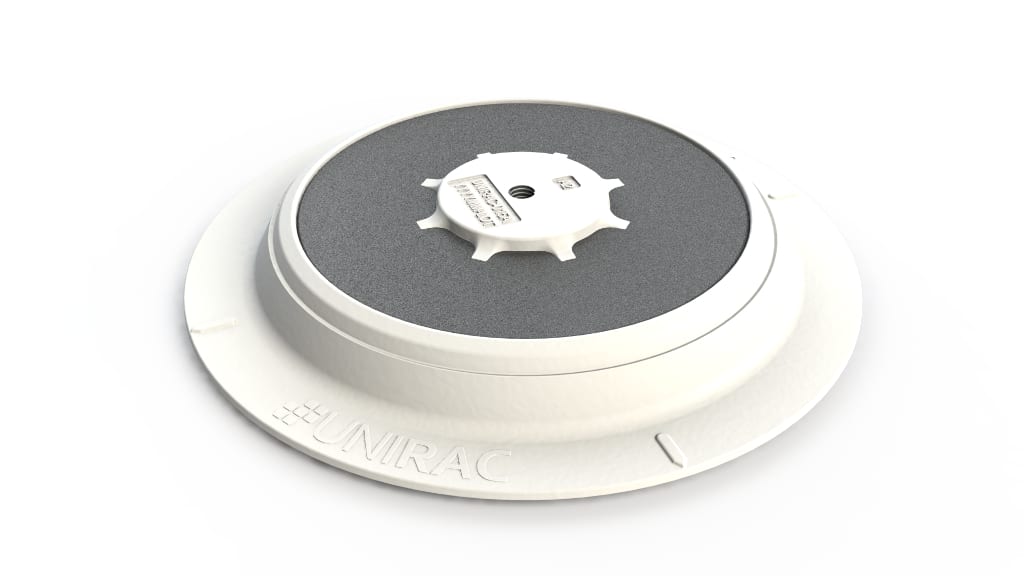

Tom brought a portable mock roof and spent the morning showing the team in detail how Unirac’s SFM Infinity rail-less system looks, feels, and works in practice, sharing his tips and tricks along the way. He also brought along samples of the new SOLOBOX junction box, new universal flat-roof attachment, and E-Boss Solartrays. Later he’ll return with the team for a trial install on a live roof.

“It’s a little different these days in that we’re wearing masks and maintaining separation, but we’ve been able to make it work,” he said. “We’ve expanded into some new virtual areas, but there’s still nothing like live, hands-on training to really get into the nitty-gritty, which helps to fully grasp the concept of a new racking system.”

The results of having a live expert able to speak to an installer’s questions are apparent. Soon after the training, Optimus posted the following on its social media:

“Thanks to Unirac for their (socially-distanced) training on many of their products today at Optimus. We are appreciative of quality manufacturers in the solar space, and Unirac has gone above and beyond on all of our projects with their components. Thankful to use this time to further train our teams and bring long-term value to clients.”

If you’re interested in hands-on training or would like more information, please contact us at: 505-242-6412.